Quality Control

Quality system

At Metalid, quality is fully integrated into every stage of our production process. We ensure precision, repeatability, and compliance with specifications across all phases of manufacturing. Using advanced 3D measurement equipment and optical analysis systems, we guarantee a high level of reliability in every delivery.

Ensuring the Highest Standards of Quality:

- Incoming and outgoing inspection of materials and components

- In-process quality control – verification at key production stages

- Systematic management of measurement equipment

At Metalid, we maintain meticulous control of all measuring instruments. A dedicated cabinet system ensures safe storage of critical tools, supporting timely calibration and recertification.

Equipment:

- Hexagon Metrology Global CMM (700×1000×660 mm; 900 kg; ±3 μm) – high precision dimensional measurements of complex components

- GOM Atos Optical Measurement System – fast and precise 3D scanning of complex geometries

Reports and Measurement Protocols:

Upon request, we provide customers with full inspection documentation (material certificates, heat treatment protocols, dimensional reports, etc.).

Do you want to verify the quality of your products? We perform third-party inspections and deliver complete dimensional reports tailored to your components.

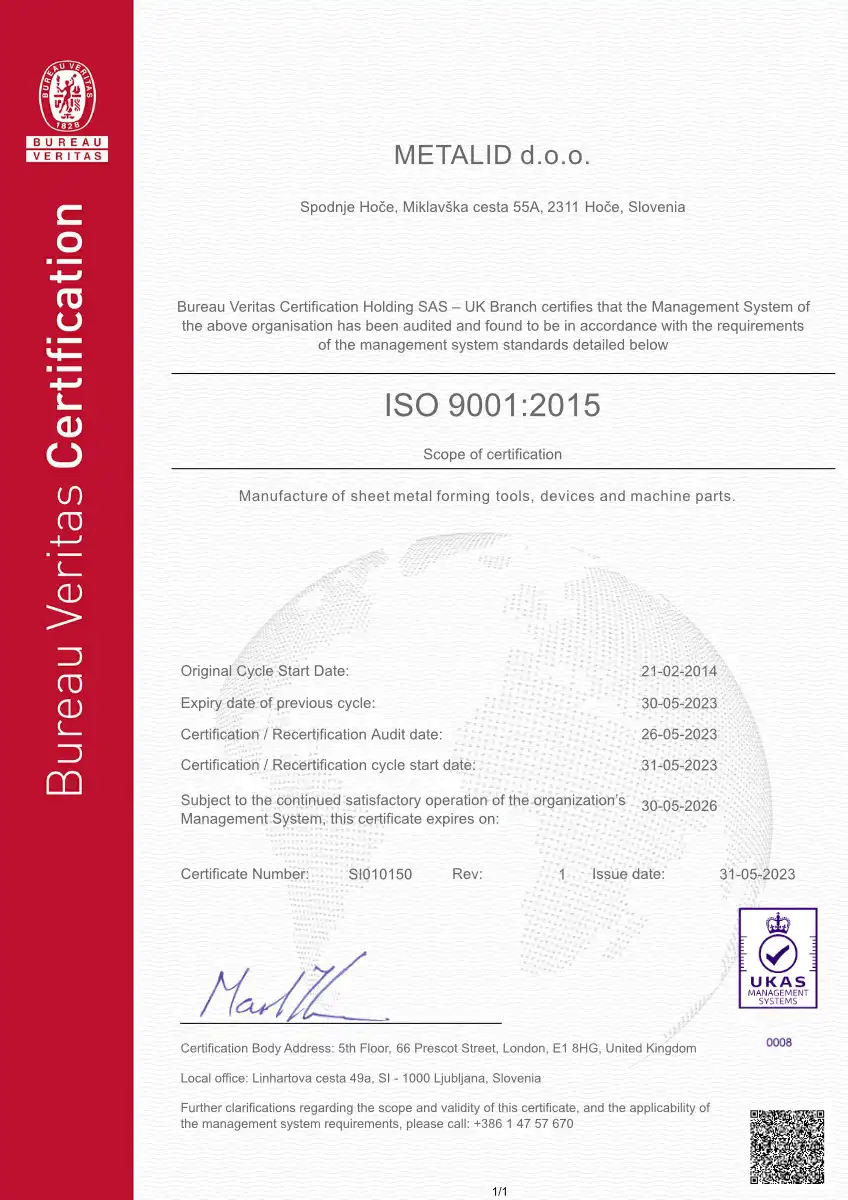

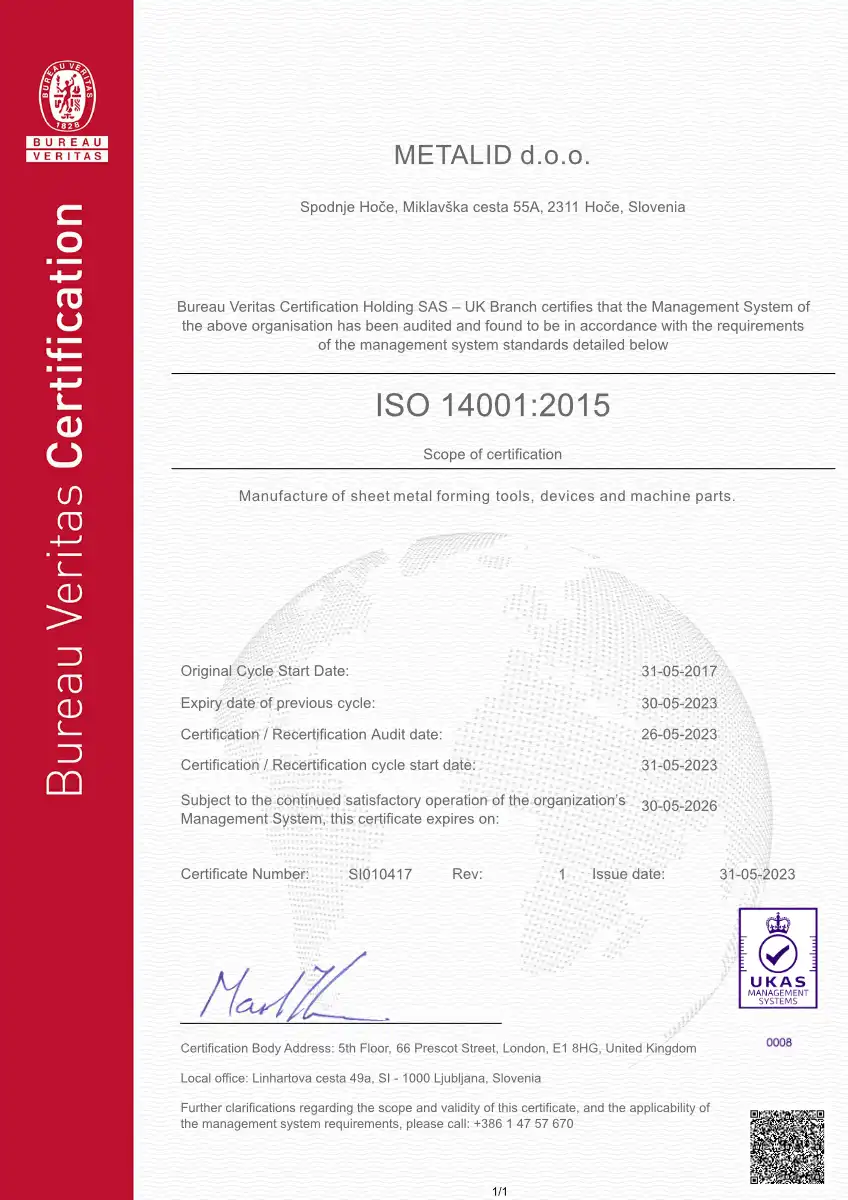

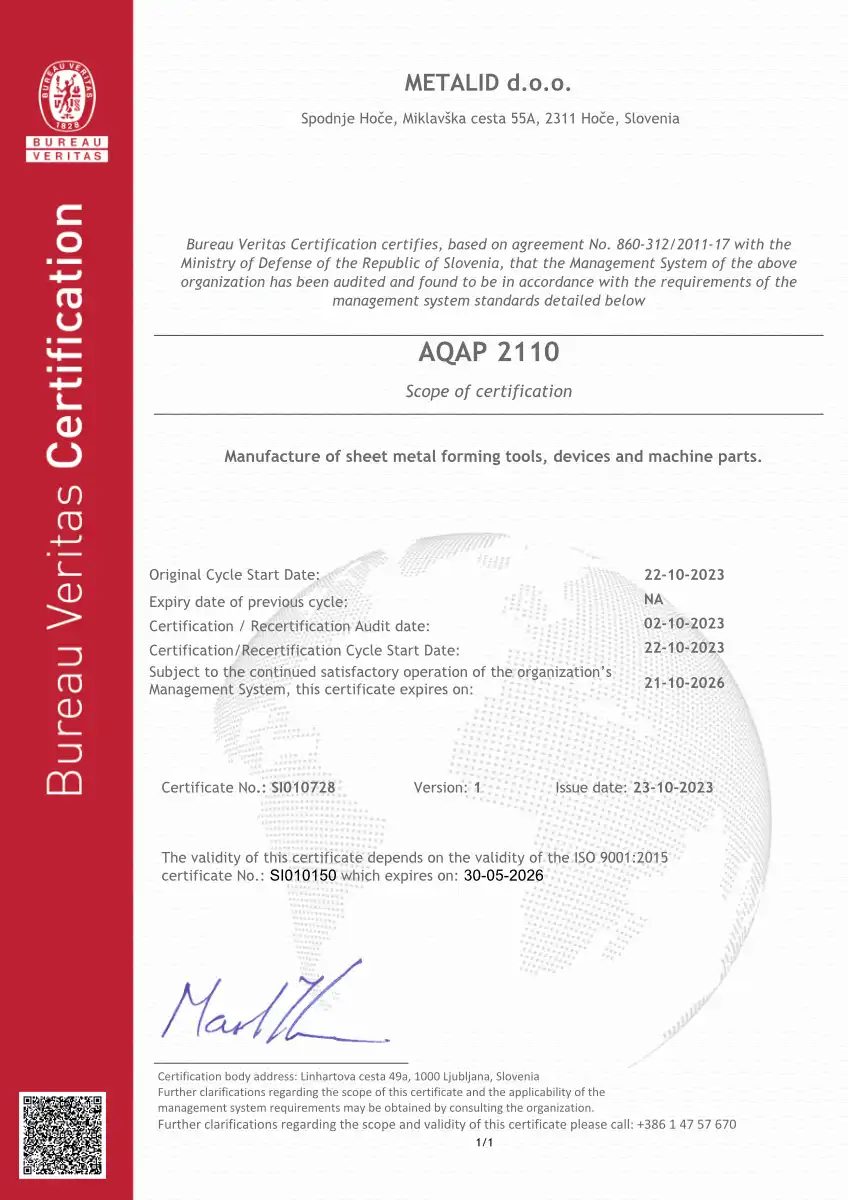

Quality Certifications

ISO 9001 – Quality Management System

Conde of conduct in company Metalid

NCAGE Code: 1592Q