CNC Turning

High‑precision CNC turning for demanding industries.

At Metalid d.o.o., we provide advanced CNC turning services for the production of high‑quality components. We manufacture both one‑off pieces and larger series. Our modern park of CNC turning machines allows precise machining of a wide range of materials — from conventional and special steels to aluminium, technical polymers and alloys.

Production automation

With years of experience and solid technical expertise, we produce turned components for demanding applications in the aerospace, automotive and electrical industries, as well as mechanical engineering.

Our series production capabilities, supplemented by robotised solutions, enable cost‑effective and repeatable results. Many of our CNC lathes are equipped with driven tools, enabling complex and precise CNC turning & milling tasks, and offering true CNC machine milling and turning flexibility.

OUR STRENGHTS

Why choose us as your CNC Turning partner?

Strong CNC turning capacities

With our machine park of six modern CNC lathes and partial automation, we are able to commit substantial monthly turning hours. We can produce turned components with diameters up to 500 mm and lengths up to 1 250 mm.

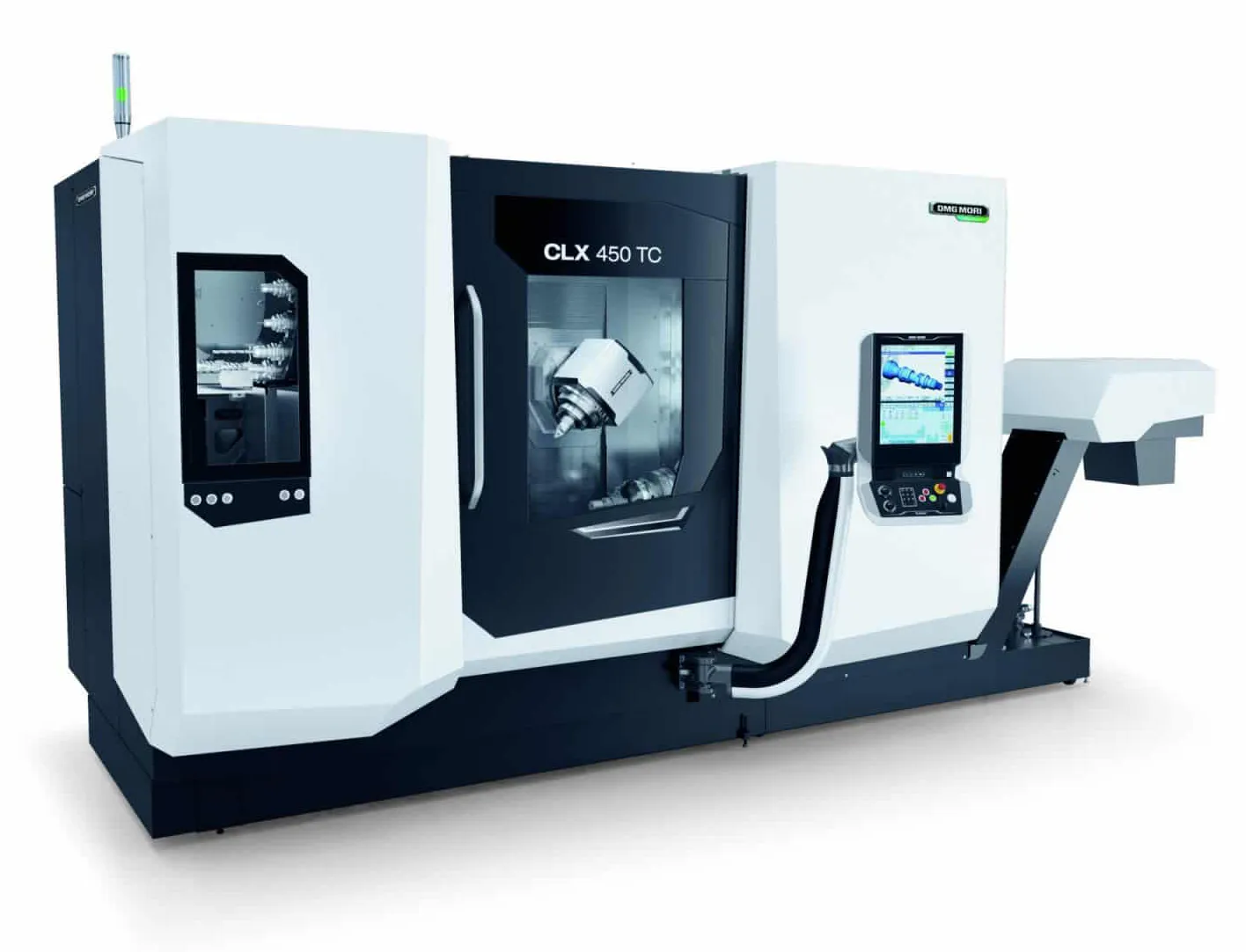

Driven tools and eccentric turning

Our turning centres are equipped with driven tooling modules and also support eccentric turning. This gives us the capability to manufacture more complex turned components in a single set‑up—improving precision, repeatability and reducing the need for post‑machining on milling centres.

High automation level

In turning we also pursue continuous improvement and production optimisation. For series work we use automatic feeders and clamping systems to ensure reliable and time‑efficient production. Our advanced robotic cell (DMG Mori Robo2Go 2nd gen) can load machines handling raw bars up to 35 kg and Ø250 mm.

Uncompromising quality

At Metalid we are committed to achieving the highest levels of quality. Our in‑house inspection and control procedures ensure traceability and guarantee compliance with relevant ISO standards, delivering precision in every turned part.

Our CNC Turning Equipment Includes:

| Machine Type | Machining Dimensions | Units |

|---|---|---|

| CNC Drehmaschine DMG MORI CLX 550 V6 – Robo2Go | Ø480 × 850 × 1 225 mm | 1 |

| CNC Drehmaschine DMG MORI NLX 2000 | Ø300 × 700 mm | 1 |

| CNC Drehmaschine DMG MORI CLX 450 – Barfeeder | Ø400 × 750 mm | 1 |

| CNC Drehmaschine DMG MORI Ecoturn 450 | Ø400 × 750 mm | 1 |

| CNC Drehmaschine DMG MORI CLX 450 TC | Ø420 × 1 100 mm | 1 |

Industries We Service

Our CNC turning services play a strategic role across highly demanding industrial sectors. With premium equipment, strong technical know‑how and extensive experience, we support:

- Mechanical Engineering: Shafts, bushes, spacers and other components. More about Mechanical Engineering →

- Aerospace: High‑precision turned elements for critical assemblies. More about Aerospace →

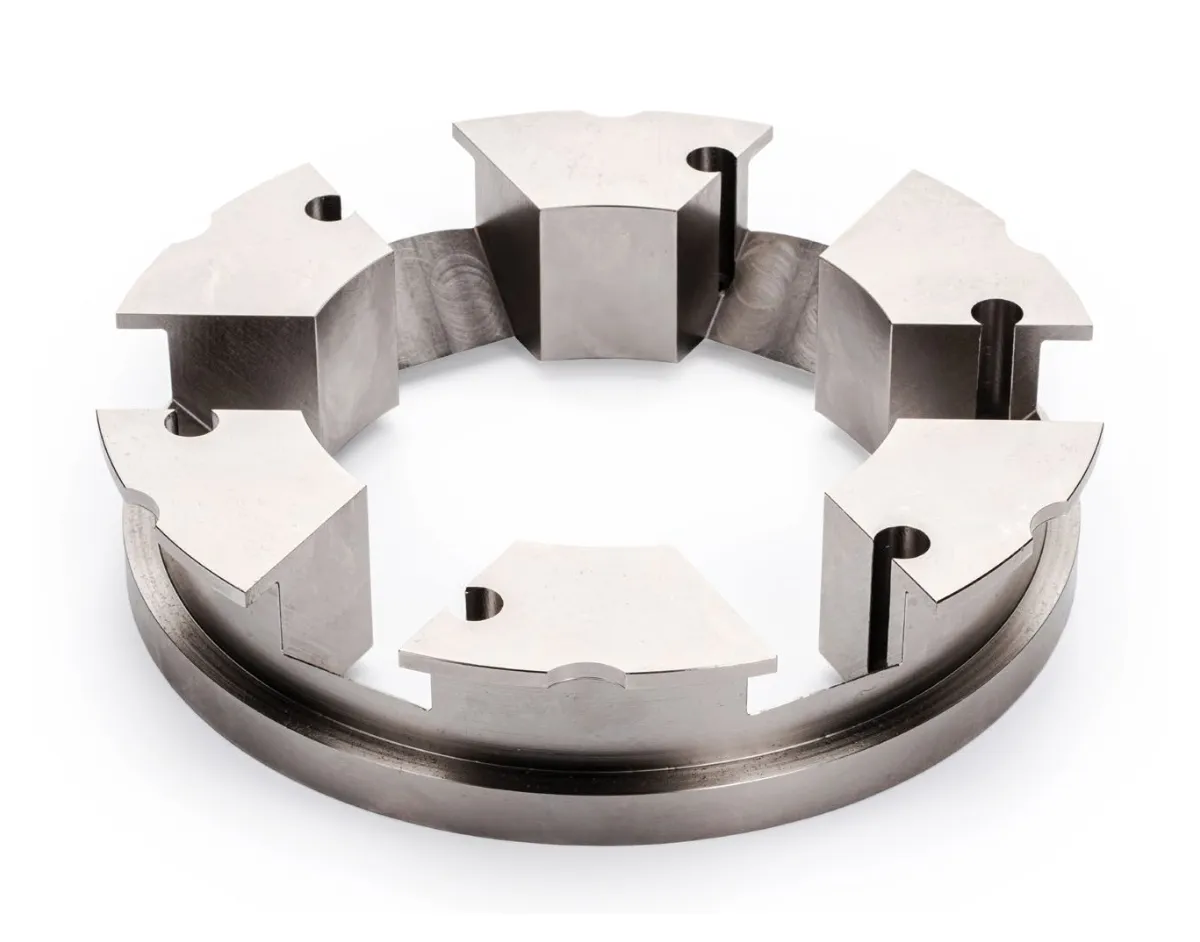

- Automotive: Components for power transmission, engines and clamping systems. More about Automotive →

- Energy Sector: Metal and insulation components for high‑tech devices. More about Energy Sector →

- Toolmaking: Elements for progressive and transfer tooling for sheet‑metal forming. More about Toolmaking →

- Defense industry: Production of safety-critical components for defense systems. More about the defense industry →

We understand the specific requirements of each sector and are technically equipped for highly complex tasks—making us a reliable partner at every project phase.