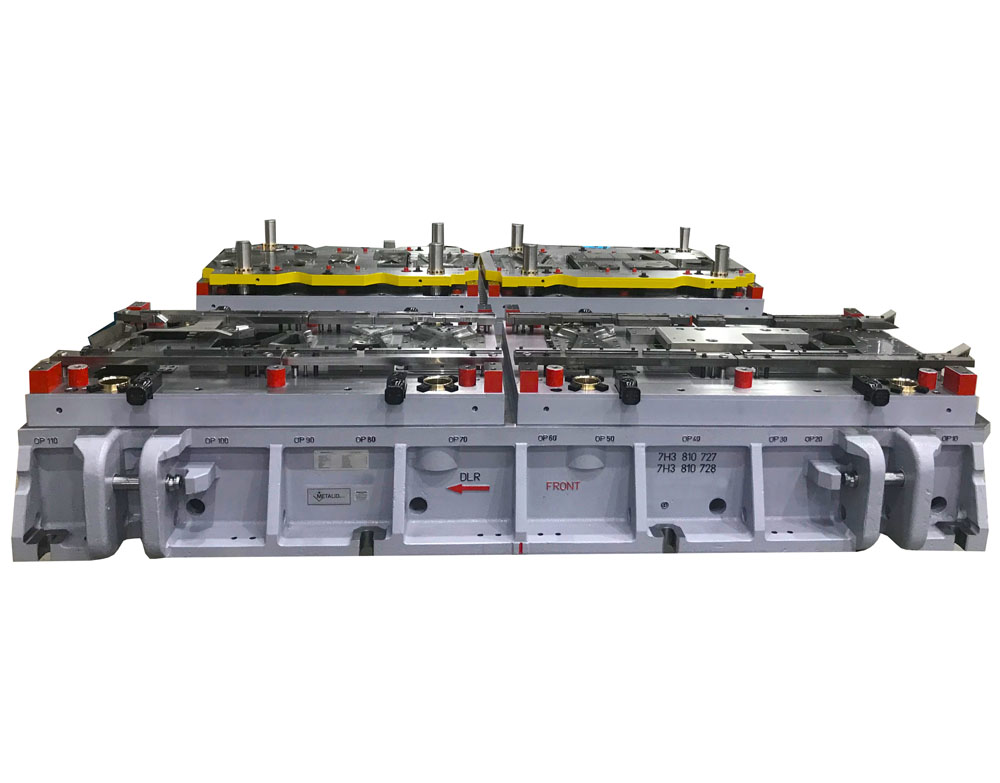

Forming tools

Progressive tools

Size up to 4000x2000x1500 mm.

On the basis of the drawing or 3D product model we prepare the production methodology, which is fundamental for the tool manufacture. The finished tool is tested on the press and a small series of products is made. We work together at the assembly of the tools and make the putting into operation of serial production possible. We ensure the minimum use of material, a long durability and a simple tool maintenance.

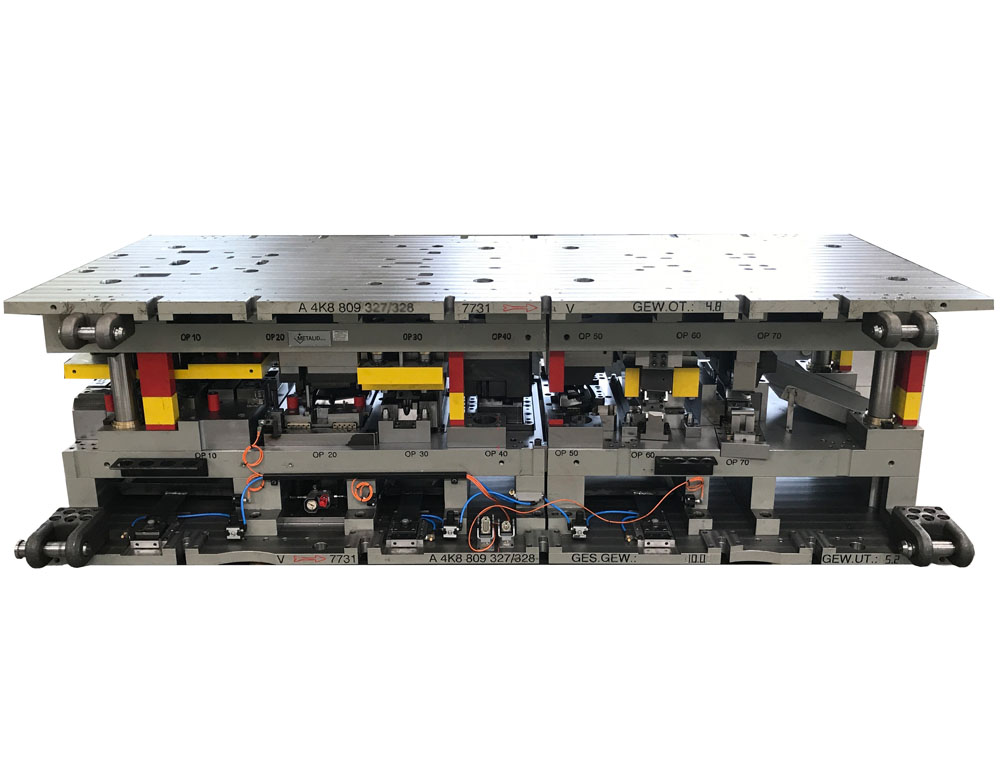

Transfer press tools

Size up to 6000x2500x1500 mm.

We manufacture transfer press tools for all sorts of forming parts. According to customers’ requests we prepare the production methodology and technology. Special attention is put on forward feed optimisation and on shortening of transfer passages. The tool can include passive or active transfer mechanisms. If necessary, we can make computer simulations of the individual stages.

Individual tools

Size up to 4000x2000x1500 mm.

We develop and manufacture individual tools with automatic or manual transfer of platinum. The tools are adapted to the customer’s press and optimised for a quick and safe handling. We seek the best compromise between durability and production cost, with emphasis on the quality.